Sustainable & digital engineering

Advanced materials

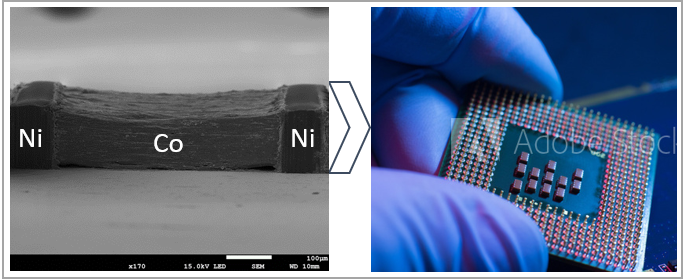

Easily integrated rare-earth-free permanent magnets

Content created on

Permanent magnets are everywhere in the technological devices that surround us. Most of these magnets require the use of expensive rare earths produced almost exclusively in China. Faced with these strategic and financial challenges, alternative solutions must be developed to reduce our dependence. The process developed here makes it possible to obtain rare-earth-free permanent magnets that meet the needs of magnet integration and miniaturisation.

COMPETITIVE ADVANTAGES

Rare earth-free permanent magnet

Manufactured at room temperature and atmospheric pressure

Process can be integrated into an industrial process

Compatible with a wide range of substrates

Little material loss

Low production costs

APPLICATIONS

- Microelectronics

- Mechatronics

- Electrical engineering

- Optomagnetics

- Health

INTELLECTUAL PROPERTY

- Patent

DEVELOPMENT STAGE

Experimental proof of concept

LABORATORY

- LPCNO

Description

The key points of the process are:

- Chemical synthesis of cobalt nanowires.

- Positioning of nickel blocks.

- Manufacture of magnets, structured and densified by magnetophoresis between the blocks.

- Removal of the blocks (or not).

- The process is carried out at room temperature and at atmospheric pressure. It meets the integration and miniaturisation constraints of permanent magnets.

Technical specifications

- Composition : Cobalt nanowires

- Substrate: Silicon, Glass, Polymer etc.

- Thickness: 10 µm < e < 1 mm

- Coercive field Hc = 470 kA/m

- Magnetic characteristic (thickness 160 µm wide 500 µm):

- Remanent induction Br = 0.6 T

- Magnetic induction B = 80 mT