Sustainable & digital engineering

Industrial Decarbonisation & innovative processes

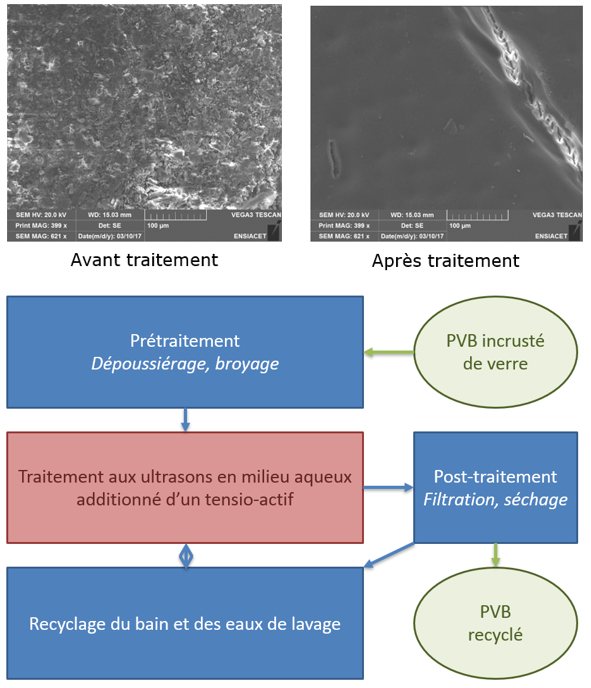

Process for producing high-quality recycled PVB

Content created on

PVB is a component of laminated glass (car windscreens, glazing, etc.), the recycling rate for which is currently very low. Tens of thousands of tonnes of PVB are produced each year from end-of-life glazing and are generally landfilled.

COMPETITIVE ADVANTAGES

- Process carried out in an aqueous medium with dilute reagents that are non-toxic, non-flammable and at low temperatures

- Equipment commonly used in industry

- Easy recycling of the reaction medium

- Method transferable to industrial scale

APPLICATIONS

- Automotive

- Architecture

- Photovoltaic cells

- Paints/Adhesives

- Cosmetics

INTELLECTUAL PROPERTY

- Expertise

- Patent

DEVELOPMENT STAGE

Laboratory validation of the technology

LABORATORY

- LGC

Description

A process consisting of detaching and/or loosening the glass splinters fixed to the PVB collected after crushing the glass parts.

Combined and complementary action of ultrasound and the effect of a surfactant added with a base at a suitable temperature not causing degradation in the polymer matrix.

Technical specifications

- Glass content after treatment: Undetectable

- Scale-up of the process carried out in the laboratory: 100g -> 1kg

- Estimated industrial cost of recycled PVB: < €1/kg